|

MUSTANG MINI TUB INSTALLATION For this demonstration we are using a 1987 Mustang hatchback. We will be showing you installation of: "Extreme Duty" frame connectors, a 12 pnt chromoly roll cage, our "SS9" rear suspension, coilover conversion, aluminum fuel cell, and mini tubs along with the frame mods needed to get the most tire room without taking the original frame out of the car. This will not be a step by step as our other instructions at this site, but as an example of how a typical Mustang is constructed.  Car is leveled up on our jack stands.

As shown, the work is in progress. Some of the roll cage is installed along with the frame connectors. For more information you can go to the roll cage installation section at this site. The mini tubs are installed and welded into place.  Another shot. Notice that the plastic panels are being finish fitted. The panels were marked out and cut before the tubs were installed.

Frame connectors completely welded. The bottom side of the outriggers shown that support the roll bar main hoop. The torque boxes are now welded.  Top view of welded frame connectors and outriggers. Shown is the main hoop welded into place.

We usually weld all around the torque boxes as shown.

A-pillar bars and roof hoop are added to cage work along with the dash bar at this time. Note clean look of the roll cage to the a-pillar of the car.

Note front outrigger shown with the a-pillar bar welded to it.

The professionals at AUTO WELD are excellent at installing roll cages. Look at the clean look of this cage up at the roof area. This is typical.

This "stub" brace is a good idea if you have a lot of horsepower and want to use a full dash. The addition of these little braces greatly increases the stiffness of the chassis. They are welded to the a-pillar bars, project through the floor and curve into the frame box as shown.

Welding a roll cage can be very difficult using a MIG welder let alone a TIG welder. Planning must be done before you start to weld so that you can complete each and every weld. This is not the place to "goof.." up. With "chromoly", NHRA rules state, it must be TIG welded!

Our "Exact Shape" mini tubs are what we say they are, "exact shape"! Look at how nice they follow the original shape of the outer wheel house. Since we are going to install a fuel cell, the back of the floor pan was cut out. Shown is the coilover crossmember tacked into place. Also notice that the tubs are MIG spot welded. Do not weld solid, the tubs will warp like crazy!

Front view of the wheel tubs. Note that roll bar plates have been installed. They are not only welded all the way around, but are actually welded directly to the torque boxes

Looking up at the back of the tub. To get the maximum amount of room, you will need to notch the frame like we do. Make sure you reinforce the frame similar to what is shown. You want to keep the frame as strong as possible.

Anther view of tub and frame notch.

Inside of wheel tub

Another view with plastic panel in place. "X" brace is welded to top torque boxes.

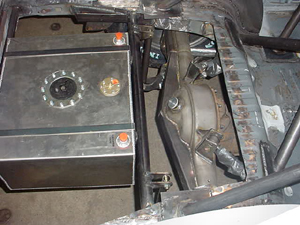

Shown here is an ideal shot of what our famous "SS9" rear suspension looks like in the car. Championships have been won with this setup. We have had a lot of magazine coverage with this rear suspension, because it "WORKS"! Also shown is how we mount one of the aluminum fuel cells sold at some of the mailorder ware- houses. Don't think you can put one of these cells in your car without a lot of modifications! First of all you must remove the tabs that are welded on the bottom of the cell. Then, since the cell is so deep, you must remove the factory trunk floor as we did. Because the fuel cell is so deep, it actually is taller than the floor surface of the trunk. So our new trunk panel had to be higher than the factory floor. At AUTO WELD we make custom fuel tanks for this reason. "TIP" Don't expect a fuel cell bought over the counter to fit your project without modifications, especially if it is a Pro-Street..er. For example,.. there are no fuel cells out there that will give you 20 gallons with 16" between the frame rails.

This a good shot of the bottom of the "SS9". Shown are the shock struts that are just for setup puposes. They will of course be changed for a set of our coilovers. By the picture you can see that our rears are built super strong.

Close-up of coilover mount. Exhaust will be run on this car. It will fit but be tight.

Fuel cell mounts are attached to shock crossmember and a 1x1 steel tube that is welded between the frame rails. Strapping and mounts are then added.

Bottom side of the fuel cell. Remember, don't get the cell too low in the car. You don't want to drag it on the ground when doing a wheel stand!

BIG meats are over 13" wide and are under the fender lip.

Rear perspective.

Another thing nice about our SS9 is that the spacer bushings that come with the kit are easily welded to the lower torque boxes. This greatly enhances the strength and durability of the bolt holes. They won't "egg" out.

Roll cage is finished. Side bars are added at this point on a job like this. Unless you like crawling over the side bars a hundred times, install last.

If TIG welding make it nice! Watch the heat!!

New floor cover welded into place. Racing sanctions require you to have protection against fire in case of a crash. Fuel cell is isolated from passenger area. A dragster style fuel access was installed. You can see the fuel cell cap under the opening.

Tires nicely tucked under.Looks great! Best of all it is going to work!!

Done! At least for us. Ready to go home for completion. Note gas fill hole has been closed. Note: For you guys that may have been with the Mustang craze for the last 15 years or so, might recognize this car. Tom D. "owner" got some magazine ink with this car as it was one of the first Mustangs to run low...12s back in the 80s. Might not sound like much now, but this was a big deal back then, because of the car being completely stock! He just wants to go faster now,...kind of like the rest of us!! We hope this page is of some help to those who would like to mini-tub their Mustang. If you need assistance, give us a call. |