|

INSTALLING A ROLL CAGE If you're considering buying one of our roll cages, the following are instructions on installing one. The tips that we show here, most race car shops are reluctant to share with you. So take your time while reading. For our puposes we are using an '86 Mustang. We are installing a "chromoly" (4130) 12 point cage with our "Extreme Duty" frame connectors, part#6601. One thing to remember, Chromoly roll bars and roll cages are required by (NHRA),to be "TIG" welded. With mild steel roll cages, you're allowed to "MIG" weld it.

#1 Put car on jack stands and level up. Cover all glass inside and out with cardboard.

#2 Plot out for frame connectors.

#3 Cut floor out 2" wide from front frame rail to, and in line with, rear frame rail.

#4 Slide Auto Weld's "Extreme Duty" frame connector up in place and then weld all the way around

#5 Frame connector welded into place.

#6 Cut the bottom of main hoop to fit outrigger, or plate, on the floor, whichever you are using.

#7 After main hoop is tacked into place, it's time to fit up the halo bar at the roof line.

#8 A homemade prop rod will hold up the front to help get ready to tack weld.

#9 Prepare the floor for the A-pillar bars.

#10 If using outriggers, first weld a plate to the side of the rocker box. This is the general procedure for attaching outriggers to the rocker box for both the main hoop and A-pillar bars.

#11 If using outriggers , you will be able to remove them ( if you tack welded them). This will enable you to drop the roll cage down in the car so you can weld the joints with ease.

#12 Weld as shown.

#13 After top joints are welded, stand main cage structure back up in the car, reinstall outriggers and weld all around. Then weld bottom legs of the main roll cage structure.

#14 Following these procedures you will be able to make a nice tight fit of the top part of the cage to the headliner. NICE!!

#15 After the seat brace and short diagonal braces are fit and welded into place, it's time to fit up the back braces. Notice the good coping job (no gaps in fit up!)

#16 Double check measurments.

#17 When welding the rear braces to the top of the main hoop, great care must be taken so you don't burn the headliner. Use a piece of sheet metal or other similar material against the headliner. This will also protect headliner from sparks. Use a hammer or something else to wedge the headliner and main hoop apart, pushing the headliner as far away from the main hoop as possible. This will give the extra clearance to weld, also creating an air gap. NOTE: You will still have to use a wet rag to keep sheet metal cool. You don't want to melt the headliner!

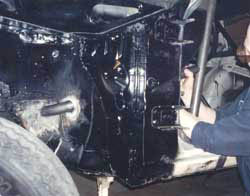

#18 View of how the short diagonal braces are attached. Always use a 6x6x1/8" plate welded to the floor before roll bar tubing is attached. The short diagonals can also be attached to the frame connectors.

#19 For this project we are also installing an "X" brace to support the upper torque box area. The object is to make the car as stiff as possible for better reaction. We use a string for a general projection of where the X-brace would be.  #20 This little device sure saves #20 This little device sure saveshours of frustration. It keeps the two tubes in-line with each other.

#21 Time to weld.

#22 Another trick we use is to run a short tube from the A-pillar tube to the front frame area. This greatly stiffens the front section of the car.  #23 The bar is being fitted. #23 The bar is being fitted.

#24 The bar is now completely welded.

#25 Here is an inside shot of the front part of the finished cage.

The above car went on to win many championships. If you follow these procedures you will have a safe, good looking roll cage. We at AUTO WELD hope these instructions help you with your project.GOOD LUCK!! #26 Cage finished! Notice the "Extreme Duty" frame connectors protruding up through the floor. NICE!! |